Rugby balls have seen a series of revolutions since their early days. The materials that these balls are made of and the methods that are followed to manufacture the balls have seen a sea change. On this page, let us discuss the change that these balls have encountered, in a chronological manner.

Revolution of Materials Used and Manufacturing Methods Used

A brief account of materials used and the process used to manufacture will give you an account of the improvement that rugby balls have undergone. Here is the brief account of the change these balls have undergone.

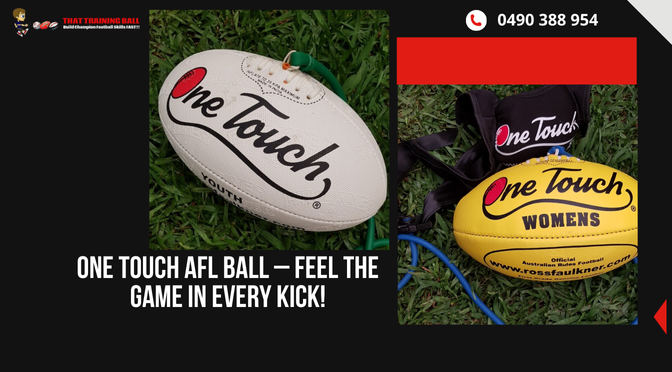

Rubber Bladders: They are now made up of the best materials for top quality balls like One Touch AFL Ball whereas in the past, pig bladders were used.

Synthetic Materials: Nowadays, balls are made up of top quality synthetic materials, which are used instead of only crude leather, to increase strength and performance under the different weather conditions.

Machine Stitching: While previously, the ball panels were hand-stitched, now high-tech machines are used to stitch the balls these days. It makes the stitches stronger and resilient to weather conditions.

Waterproof Coatings: The modern balls feature high quality waterproof coatings, which are applied to make the modern balls playable in wet, muddy conditions.

These transformations have gone a long way to manufacture top-quality rugby balls, which the trainees can use for rigorous training sessions. The reason being, these balls are reliable and resilient.

The Evolving Technology of Rugby Ball

The technology of rugby ball manufacturing has undergone a sea change over the past few decades. These innovations have helped the players perform better on the pitch. Besides, they have made the games more competitive and interesting. The modern training balls, like the One Touch football, helps today’s trainees train with more vigour and master the skills faster and with more perfection as well as authority.

The Modern Waterproof Technology

The modern rugby balls are designed to excel in any pitch or weather condition. One of the most remarkable features that modern rugby training balls come with, is use of top quality waterproof coating. These coatings keep these balls light and handy even when they get wet. These coatings prevent the water from being soaked by the material. If the material of a ball absorbs water, the ball gets heavier and the grip of the ball changes markedly.

Besides, the manufacturers today pay special attention to the seams and the stitching. This prevents the water from letting in too easily. This makes these parts of the modern balls stronger and ensures their performance is optimum. Players need a predictable grip regardless of the weather and pitch conditions. This improved stitching helps the balls available in the sporting goods store to be in top condition and perform optimally.

Aerodynamic Improvements

The design of a rugby ball is heavily dependent on aerodynamics. The advanced aerodynamic technology that is followed makes passes and kicks more accurate. Moreover, advanced aerodynamics also stabilises the flight. The texture of the surface of the modern rugby balls are designed to reduce the drag, apart from improving grip.

Therefore you see, when you get the modern training balls from That Training Ball, you enjoy these privileges. Call us at 0490 388 954 to place the order for the ball of your choice.